Understanding the structure of a touch screen is key to choosing the right display technology. In this article, we explore the key components and bonding methods of LCD touch screens, focusing on both capacitive and resistive technologies.

1. What Is a Touch Screen? Introduction to LCD Technology

LCD (Liquid Crystal Display) is a popular display technology that relies on the properties of liquid crystals to present visual content. Thanks to its energy efficiency, thin profile, and wide viewing angle, it is widely used in smartphones, tablets, and wearables.

When combined with touch screen functionality, the display becomes interactive, enabling operations like tap, swipe, and pinch. An LCD Module (LCM) typically consists of the LCD panel, backlight unit, touch panel (TP), and controller circuitry.

The market mainly features two types of touch technology: capacitive and resistive. Both have different structures and applications.

2. Capacitive vs. Resistive Touch Screens: Key Differences

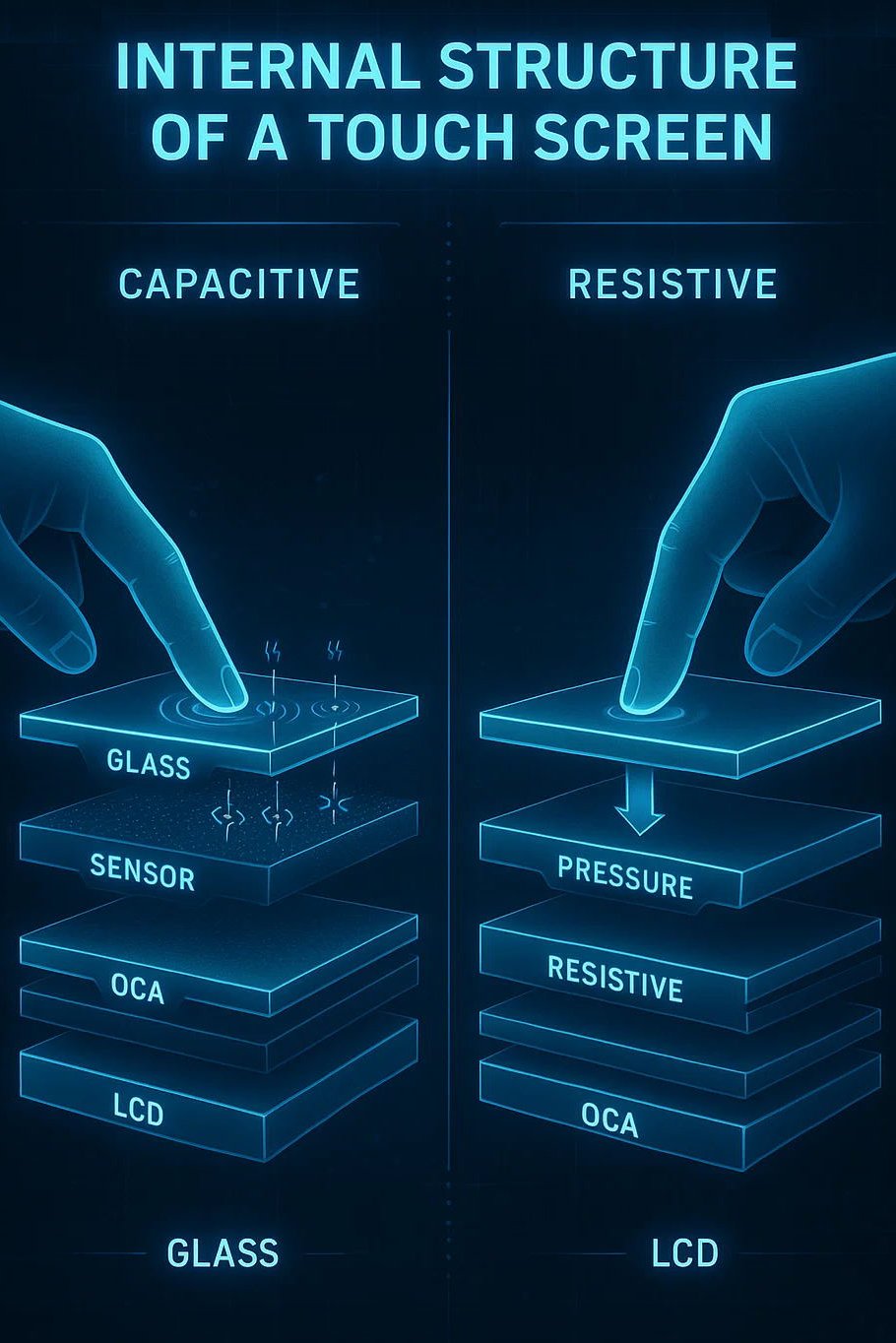

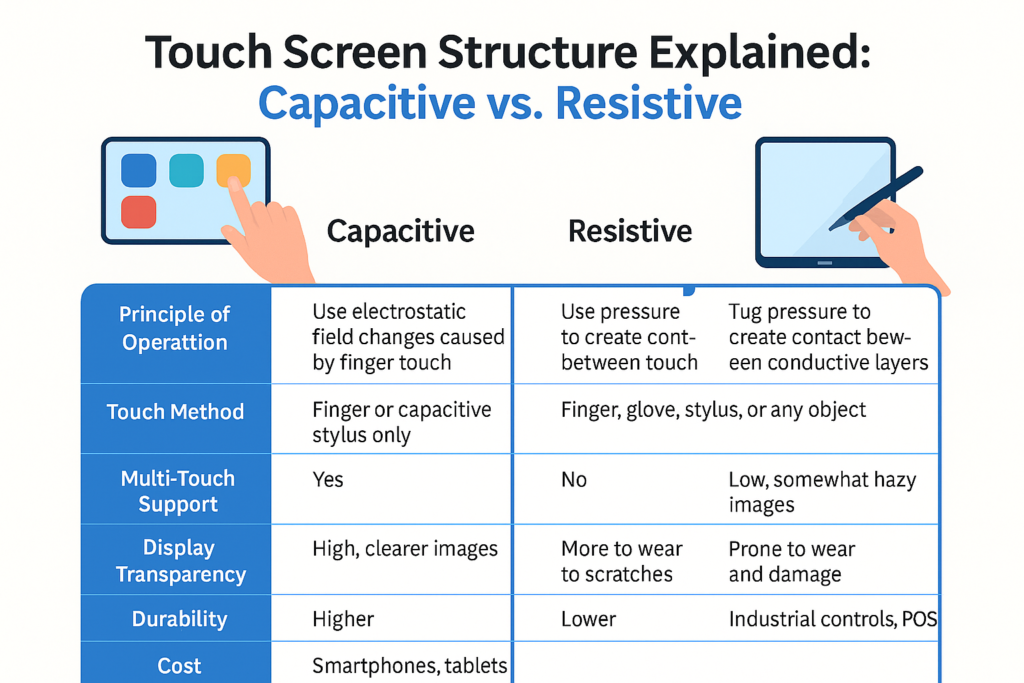

Working Principle

Capacitive: Detects electrical current from the human body. Touching the screen disturbs the electrostatic field, and the controller calculates the touch position based on changes in current at the screen’s corners.

Resistive: Relies on pressure. Pressing the flexible top layer makes contact with the bottom layer, triggering a signal.

Touch Performance

– Capacitive: Multi-touch support, fast response, and high precision.

– Resistive: Single-touch, works with any stylus, gloved fingers, or object.

Environment Suitability

– Capacitive: Sensitive to humidity, temperature, and electrical noise.

– Resistive: Resistant to dust, moisture, and extreme temperatures.

Cost and Durability

– Capacitive: Higher cost, longer lifespan due to reduced wear.

– Resistive: More affordable but wears out faster due to pressure-based input.

3. Screen Bonding Methods: Frame vs. Full Lamination

Frame Bonding

Also called ‘tape bonding,’ this method uses double-sided tape around the borders to attach the TP and LCD. It’s cost-effective but leaves an air gap, reducing display clarity and allowing dust to enter.

Full Lamination (OCA)

Full lamination involves bonding the TP and LCD seamlessly using OCA (Optically Clear Adhesive) or liquid glue. This improves screen transparency, enhances touch responsiveness, and strengthens the screen assembly. Additionally, it reduces internal reflection and electromagnetic interference.

Popular full lamination techniques include OGS (One Glass Solution), On-Cell, and In-Cell technologies.

4. Frequently Asked Questions (FAQ)

Q1: What is the structure of a touch screen?

A1: A typical touch screen includes a cover lens, touch panel (TP), and LCD. These layers are assembled using either frame bonding or full lamination.

Q2: What’s the difference between capacitive and resistive touch screens?

A2: Capacitive screens detect electric current and support multi-touch. Resistive screens rely on pressure and work with any object.

.png)