Selecting the right Industrial Panel PC can be a complex task, but it doesn’t have to be. A wrong choice can lead to equipment failure, project delays, and budget overruns. To ensure you invest in a device that is reliable, durable, and perfectly suited to your needs, follow this proven four-step process.

Here’s your no-mistakes guide to choosing the perfect industrial touchscreen computer:

- Define Your Requirements

- Evaluate the Manufacturer

- Assess Build Quality and Materials

- Verify Production and Testing Standards

Step 1: Clearly Define Your Requirements

The best Industrial Panel PC is the one that fits your specific application perfectly. Before you start Browse, create a detailed checklist of your needs. This should include the operating environment, installation method, screen size, and system configuration.

1. Operating Environment The environment dictates the build of the PC.

- For extreme temperatures (hot or cold), you need a unit with a wide operating temperature range.

- For industrial sites with high levels of dust or humidity, an embedded or fully enclosed panel PC is essential. These designs offer superior protection against dust and water ingress.

2. Installation and Dimensions Common installation options include wall-mounted, desktop, and embedded (panel-mount). Measure your available space to determine the right size and mounting type.

A critical rule for embedded installations: Finalize the PC model before cutting any openings in your equipment. It is far more difficult to find a device that fits a pre-existing hole. Always consult the manufacturer for precise cutout dimensions.

3. System Configuration (CPU, RAM, Storage) Define your performance needs based on the software you will run. While higher specs are tempting, they also increase costs. Choose a configuration that matches your actual requirements to avoid the “overkill” scenario—paying for power you’ll never use.

Step 2: Thoroughly Evaluate the Manufacturer

Your manufacturer is your partner. Look beyond the product and evaluate their scale, credentials, R&D capabilities, supply chain, and after-sales support.

1. Company Scale and Scope The size of a manufacturer often reflects its capabilities. A larger, well-established company typically has a comprehensive service system covering product design, in-house fabrication, touchscreen R&D, and complete assembly. This indicates strong, reliable operations.

2. Professional Certifications Reputable manufacturers hold key industry certifications. Look for:

- Quality & Safety: ISO9001, 3C, CE, FCC, RoHS

- Business Standing: High-Tech Enterprise Certificates

- Government Projects: Energy-saving and environmental protection certificates are often mandatory for public sector procurement.

3. R&D and Customization Capabilities Industrial Panel PCs often need to connect to and control other equipment. Does the manufacturer offer the specific I/O ports you need? More importantly, can they customize the interfaces if your project requires it? Strong R&D is a sign of a flexible and capable partner.

4. Supply Chain Stability A stable and transparent supply chain is crucial for quality and availability. Ask if the manufacturer partners with reputable brands for critical components like processors, memory, and displays. This ensures consistent product quality and reliable delivery schedules.

5. After-Sales Support This is one of the most critical yet frequently overlooked factors. A top-tier manufacturer provides more than just a great product; they offer a professional technical team and a robust after-sales service framework. Look for comprehensive warranty policies and lifetime repair services to ensure you have support for the entire lifecycle of the product.

Step 3: Assess Build Quality, Materials, and Performance

The physical components of an Industrial Panel PC determine its durability and usability.

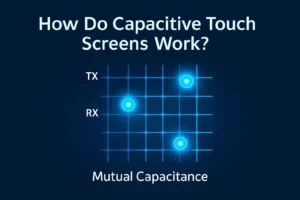

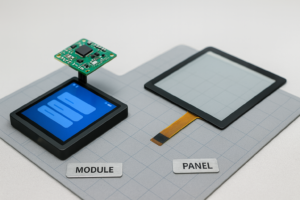

1. Touchscreen Technology While resistive and infrared screens exist, projected capacitive (PCAP) is the current industry standard. PCAP touchscreens offer superior sensitivity, higher accuracy, and support for 10-point multi-touch with a fast, responsive feel.

2. Core Performance Specs For true industrial-grade performance, look for these benchmarks:

- Durability: A screen with a Mohs hardness rating of 6H or higher for explosion-proof and scratch-resistant performance.

- Ingress Protection: An IP65-rated front bezel for protection against dust and water jets.

- Interference Resistance: The ability to pass stringent EMC anti-interference testing, which is vital for use near other electronic machinery.

3. Chassis Material The three main materials are aluminum alloy, sheet metal, and plastic.

- Aluminum Alloy: Highly recommended. It is up to 40% lighter than traditional sheet metal, offers excellent heat dissipation, and provides superior corrosion resistance and insulation.

- Sheet Metal: Heavier and more robust, making it suitable for applications where a heavy, stable enclosure is needed. It is also a more budget-friendly option.

- Plastic: Not recommended for most industrial control applications due to its lower durability and heat tolerance.

4. Industrial-Grade Motherboard An Industrial Panel PC should use a dedicated industrial motherboard, typically built with a 6-layer PCB. This design offers powerful protection, enhances electromagnetic compatibility (EMC), and improves oxidation resistance, ensuring the device can operate efficiently 24/7 without interruption.

Step 4: Verify the Production and Testing Process

From R&D to final shipment, a reliable Industrial Panel PC must undergo a series of rigorous tests to guarantee its quality. Ask the manufacturer about their testing procedures, which should include:

- Vibration and Drop Tests

- Constant Temperature and Humidity Tests

- Pressure and Stress Tests

- Burn-in (Aging) Tests

- Touchscreen and Display Calibration Tests

Conclusion: A Summary for Smart Buying

To summarize, choosing the right Industrial Panel PC is a strategic process.

First, define your needs. Second, select a capable manufacturer. Third, scrutinize the materials and performance specs. And fourth, confirm their production and testing standards.

By prioritizing your requirements and choosing a manufacturer with proven, time-tested products, you can confidently invest in a high-quality Industrial Panel PC that will serve your operations for years to come.

.png)