Modern CNC (Computer Numerical Control) machines rely heavily on high-performance displays to ensure precision, ease of use, and real-time feedback. As we delve into CNC machine display solutions, we explore various display technologies, interface options, and touchscreen systems designed to improve the efficiency of CNC machinery.

Table of Contents

- What Is a CNC Machine?

- Types of Displays Used in CNC Machines

- Touchscreen Technologies in CNC Interfaces

- How Displays Improve CNC Precision and Efficiency

What Is a CNC Machine?

CNC stands for Computer Numerical Control. These machines are operated by pre-programmed computer software, automating tasks that would otherwise be performed manually. Displays play a key role in CNC systems by providing real-time visual feedback, operational controls, and safety alerts.

Types of Displays Used in CNC Machines

- OLED Displays: Provide excellent image quality and wide viewing angles but are more expensive.

- LCD Screens: The most commonly used in CNCs today, available in both monochrome and color versions.

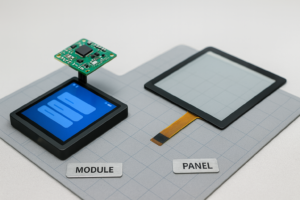

- Touchscreens: Enable direct interaction. Includes resistive and capacitive technologies.

- LED Displays: Known for high contrast and brightness with improved energy efficiency.

- CRT Monitors: Still found in legacy systems but are gradually being phased out.

Touchscreen Technologies in CNC Interfaces

Modern CNC interfaces integrate touchscreens for simplified control. Here’s how the two main types compare:

Resistive Touchscreens

- Operate through pressure.

- Work with gloves or stylus.

- Less expensive and ideal for dusty or extreme environments.

- Only supports single-point touch.

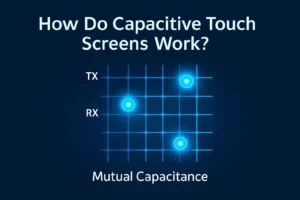

Capacitive Touchscreens

- Respond to electrical conductivity (e.g., a human finger).

- Supports multi-touch gestures.

- Faster and more fluid user experience.

- Common in modern HMI panels.

These touchscreens are often paired with hardened glass to resist scratching and mechanical damage, especially in industrial settings.

How Displays Improve CNC Precision and Efficiency

- Display critical data such as cutting speed, tool coordinates, and diagnostics in real time.

- Enhance monitoring with graphical dashboards and 3D simulation capabilities.

- Allow direct editing and code programming on the machine via touch interface.

- Support integration with ERP, MES, and IoT systems to enable Industry 4.0 connectivity.

- Visualize tool paths before operation to reduce errors and material waste.

Advanced CNC displays help operators identify issues quickly, minimize downtime, and increase production accuracy.

Conclusion

Investing in advanced display solutions for CNC machines brings measurable benefits in usability, productivity, and safety. Whether choosing LVDS, RGB, or a specific touchscreen type, the right interface makes all the difference.

Looking to upgrade your CNC display solution? Contact us today to explore our full catalog of industrial LCD-TFTs, touchscreens, and embedded systems.

.png)