Panel PC = touch + computing in one device. Touch monitor = touch display only, with an external industrial PC. If you want fewer cables and faster deployment, choose a Panel PC. If you want flexible maintenance and scalable compute (GPU, capture cards), choose a touch monitor + IPC. Below you’ll find comparisons, use cases, TCO, and a buyer checklist.

Read this first (30‑second summary)

- Definition: Panel PC = touch + computing. Touch monitor = touch + external host.

- Rule of thumb: High integration/less cabling/faster rollout → Panel PC. High flexibility/expandability/thermal separation → touch monitor + IPC.

- Typical combos: Line HMI (15.6/21.5″ Panel PC); retrofit (touch monitor + cabinet IPC); vehicle/warehouse (10–12″ high‑brightness Panel PC); outdoor kiosk (high‑brightness touch monitor + split host).

Basics and architecture

What is an industrial Panel PC?

An all‑in‑one unit with display, PCAP touch, and the computing platform inside. Often with a front IP65 bezel, glove/wet‑hand support, and configurable I/O. For typical HMI stacks (glass, bonding, sensor), see OCA vs LOCA.

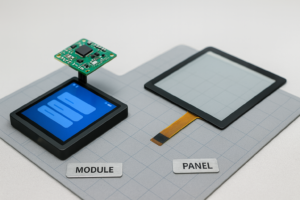

What is a touch screen monitor?

A touch display that connects to an external industrial PC. Ideal for high compute, expansion, multi‑screen walls, or thermal separation. If you are weighing a module vs panel approach, read Touch Screen Module vs Panel.

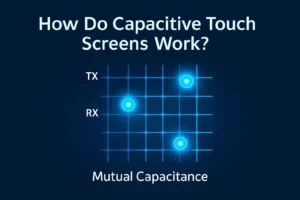

Shared stack and touch technology

Both use a cover glass, optical bonding (OCA/LOCA), PCAP sensor, backlight, and EMI shielding. PCAP (mutual capacitance) is the default; resistive is an option for special gloves/chemicals. New to multi‑touch? Start with How capacitive multi‑touch works and the Capacitive touch technology deep dive.

When to choose which

Choose a Panel PC if you need…

- Space‑constrained installs, fewer cables, fast deployment

- Local compute to reduce latency and noise

- Single, unified EMC/IP/IK certification for the device

- Mobile/vehicle/forklift environments with vibration

- One‑piece maintenance and spare parts

For real‑world HMI builds and certifications, see our Industrial HMI solutions.

Choose a touch monitor if you need…

- High compute/expandability (GPU/capture cards/multi‑NIC)

- Modular maintenance, video walls, or thermal separation

- Reuse of an existing cabinet IPC

- Tight domain certifications (e.g., medical EN 60601) requiring split design

Considering whether to scale up to a full Panel PC later? Our Industrial Touch Screen Buyer’s Guide covers lifecycle planning and upgrade paths.

Hybrid option

Touch module + external embedded board (ODM). Keep the front‑end light while allowing host upgrades. See the pros/cons in Module vs Panel.

Key spec comparison

| Dimension | Panel PC | Touch monitor |

|---|---|---|

| Display & optics | 7–21.5″; 800–1500 nits; OCA/LOCA; AG/AR/AF | Same options; custom glass/mechanics per project |

| Touch experience | PCAP multi‑touch, glove/water rejection, palm suppression | Same; controller can be tuned for scene |

| Compute | Built‑in Intel/ARM; low latency | External IPC with free choice of CPU/GPU/cards |

| I/O & expansion | HDMI/DP/USB/RS‑232/485/LAN/DI/DO/M.2 | Video (HDMI/DP) + USB‑HID touch; expansion on IPC |

| Environment | Front IP65, IK07; wide temp/vibration options | Front IP65 possible; overall depends on IPC mounting |

| Mounting | Panel/Wall/VESA/Open‑frame | Same; IPC location is flexible |

| Maintenance | One‑piece swap; higher spare cost per unit | Modular replacement; shorter downtime |

| Initial cost | Higher (includes host) | Lower (display only) |

| TCO | Less cabling/installation; spare cost higher | More wiring; friendlier long‑term service |

Use cases & recommended combos

Line HMI / SCADA

15.6″/21.5″ Panel PC with front IP65, USB‑HID touch, Modbus/TCP; 1000 nits + OCA for bright floors. See our Industrial HMI solutions for examples.

Equipment retrofit

Touch monitor + cabinet IPC to preserve existing control cards and expandability. For touch component choices, review capacitive touch technology.

Warehouse & vehicle

10.1–12.1″ high‑brightness Panel PC, 9–36 V, anti‑vibration mounting, GNSS/LTE/Wi‑Fi options. Learn how multi‑touch sensing adapts to gloves and moisture.

Medical / cleanroom

Touch monitor + isolated IPC for easier disinfection and EN 60601 routing. Bonding and coatings options are summarized in OCA vs LOCA.

Outdoor kiosk

High‑brightness touch monitor + split host, front IP65, AG/AR/AF; external IPC for heat management. Compare stack choices in Module vs Panel.

TCO framework

- Capex vs installation: Panel PC saves wiring and labor; touch‑monitor setups start cheaper.

- Downtime: Panel PC = one‑piece swap; modular setups shorten troubleshooting time.

- Lifecycle & sourcing: Confirm 5–7 years supply, alternates, and EOL clauses—see our buyer’s guide.

- Thermals & power: Large/high‑brightness displays need careful thermal design.

Buyer checklist (12 items)

- Application & environment (dust/oil/chemicals/outdoor)

- Size & brightness (sunlight readable? polarization)

- Touch needs (multi‑touch, glove, water rejection)

- Compute & I/O (for Panel PC)

- IPC placement & cooling (for touch monitor)

- Mounting & cutout drawings

- IP/IK, EMC/ESD targets & tests

- Power range & isolation (9–36 V)

- OS/drivers & application software

- Remote management & security (TPM/whitelist/OTA)

- Certifications (CE/FCC/EN 60601/E‑Mark)

- Lead time, MOQ, spares & RMA

Need help filling this out? Start with the Industrial Touch Screen Buyer’s Guide or talk to our HMI team.

.png)