Introduction

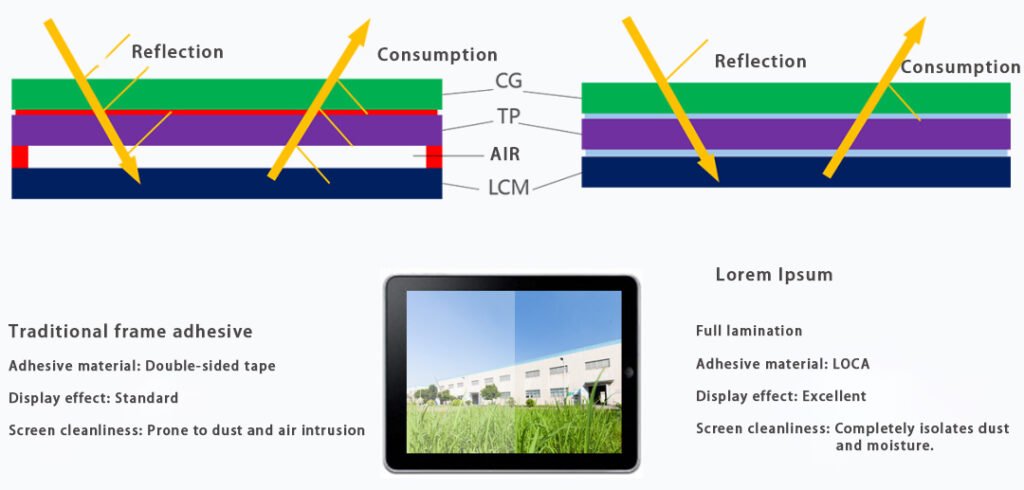

In the touch display industry, bonding methods mainly include frame bonding and full lamination. Frame bonding leaves an air gap, which can cause light refraction and lead to poor optical performance. In contrast, full lamination involves seamlessly bonding the Touch Panel (TP) to the Liquid Crystal Module (LCM) using optical adhesive, improving light transmittance and display clarity.

Comparison Between Full Lamination and Frame Bonding

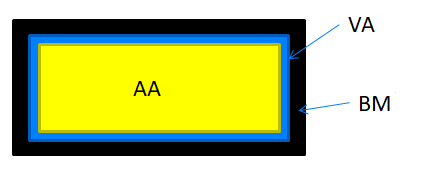

The View Area (VA) and the surrounding Black Matrix (BM) area affect how light is transmitted through the display. Full lamination provides a seamless interface that enhances display performance compared to frame bonding.

1. Structure of Capacitive Touch Screens (TP)

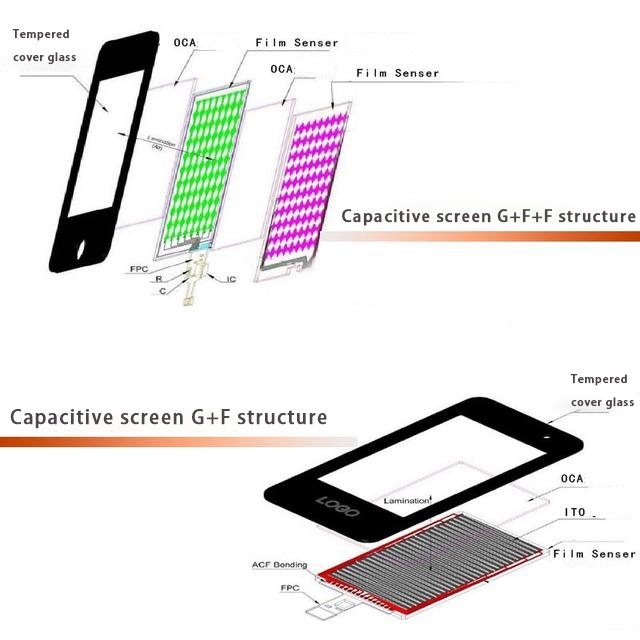

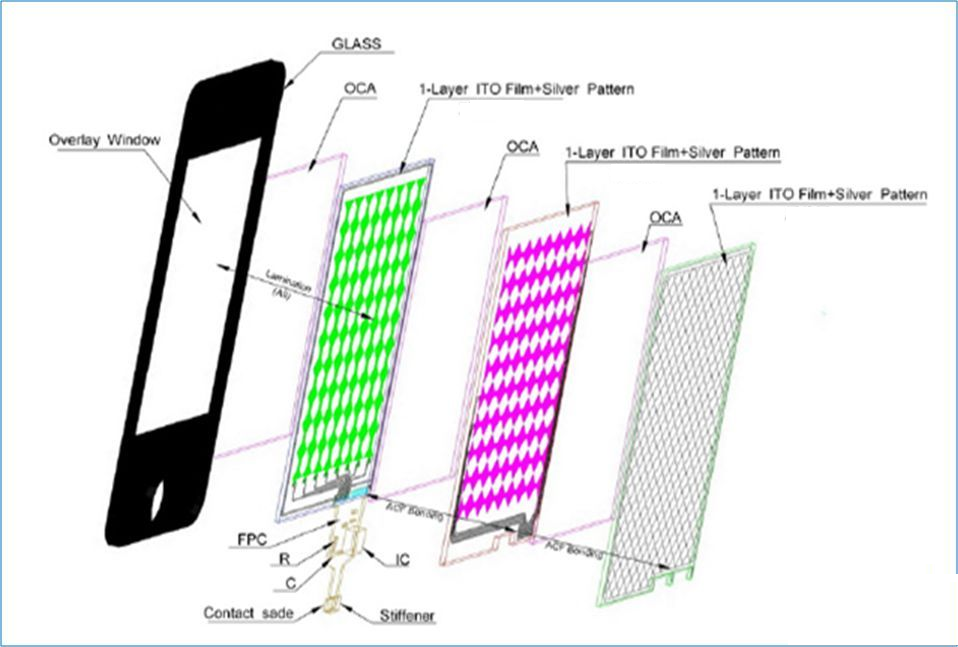

Capacitive touch panels are typically categorized into G+G, G+P, and G+F structures. The first letter indicates the surface material (top layer), and the second refers to the sensing layer (bottom layer). ‘G’ stands for Glass, ‘F’ for Film, and ‘P’ for Plastic (PC). The ‘+’ symbol indicates bonding.

• G+F: Supports single-point touch only

• G+G or G+F+F: Supports multi-touch functionality

1) G+F Structure

This structure consists of a tempered glass cover + OCA (optical clear adhesive) + Film Sensor. The glass cover provides protection and enhances surface texture, while the OCA ensures strong adhesion and transparency. The Film Sensor layer is responsible for touch signal detection. This configuration is suitable for screens smaller than 3.5 inches and is a cost-effective option.

2) G+F+F Structure

Compared to G+F, the G+F+F structure adds an extra Film Sensor layer, enabling multi-touch support. This configuration results in thinner screens but comes at a higher cost. As plastic (PET) can’t have circuits on both sides like glass, two layers of film are necessary for multi-touch.

3) G+G Structure

G+G (Glass + Glass) includes a tempered glass cover and a glass sensor. It is highly durable, resistant to scratches and corrosion, offers high transparency, and provides smooth operation. Its surface hardness can exceed 8H, making it highly scratch-resistant and reliable.

4) G+P Structure

This structure includes a glass cover and a PC (polycarbonate) touch sensor layer. While it is cost-effective and easy to manufacture, it lacks durability, has lower optical performance, and reduced reliability.

2. Principles of Capacitive Touch Screens

Capacitive touch screens are categorized into:

• Surface Capacitive Touch

• Projected Capacitive Touch

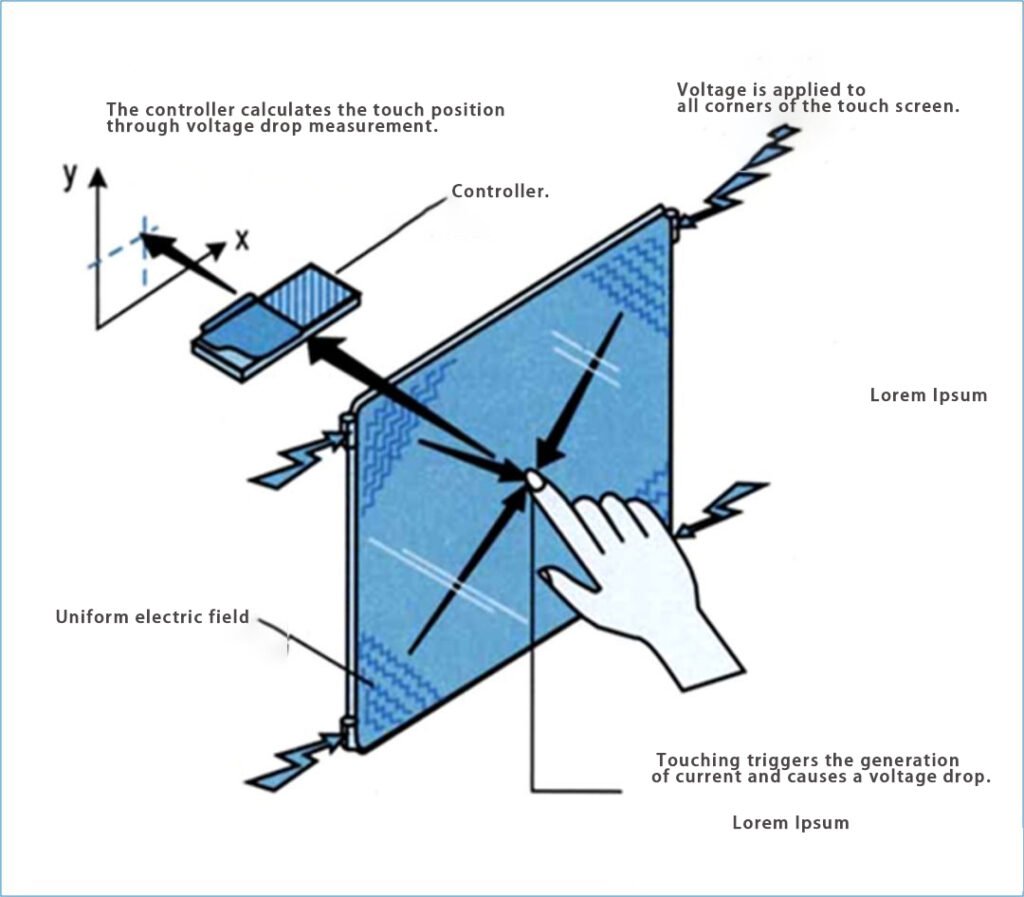

1) Surface Capacitive Touch

When a user touches the screen, the body’s natural electric field forms a coupling capacitor with the conductive layer. Current flows from the four corners toward the touch point, and the strength is proportional to the distance from the electrodes. A processor calculates the touch point based on current strength.

Advantages:

1. Sensitive to light touch and easy to use; minimal wear due to no mechanical interaction.

2. Susceptible to drift, not suitable for metal enclosures, and sensitive to EMI and magnetic fields.

2) Projected Capacitive Touch

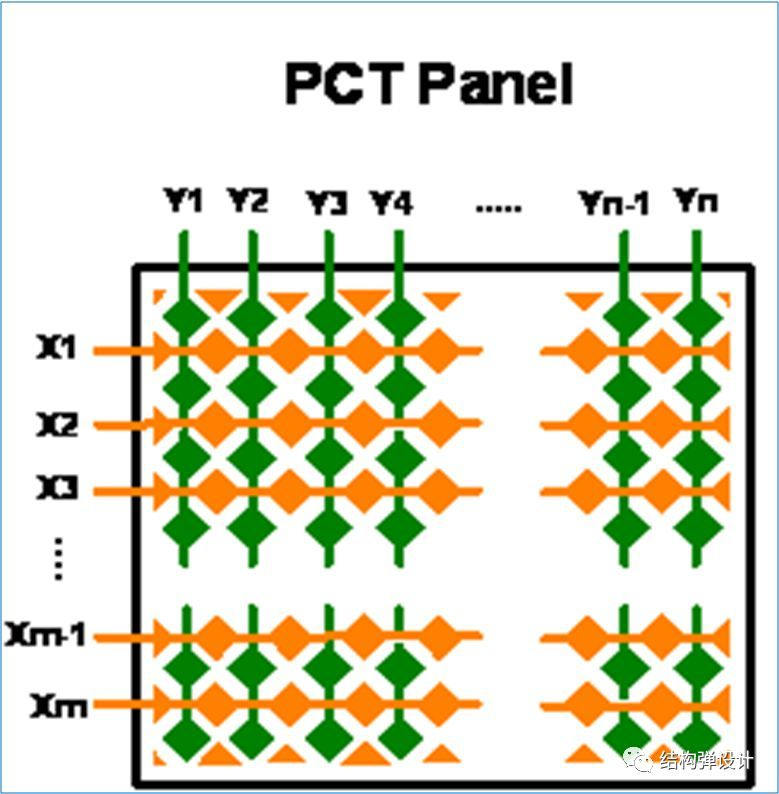

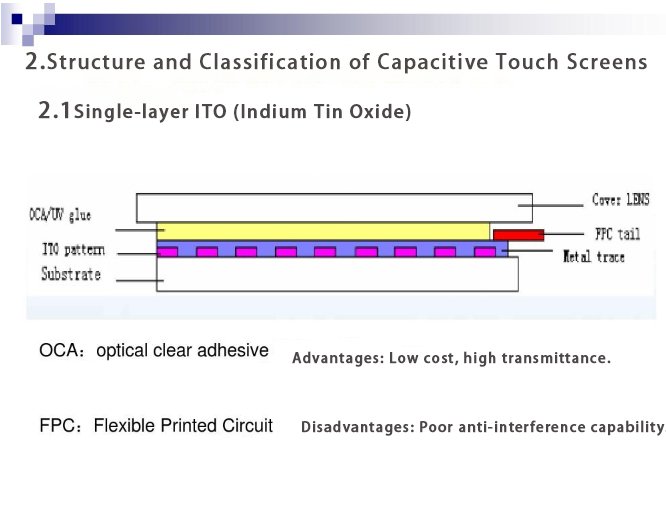

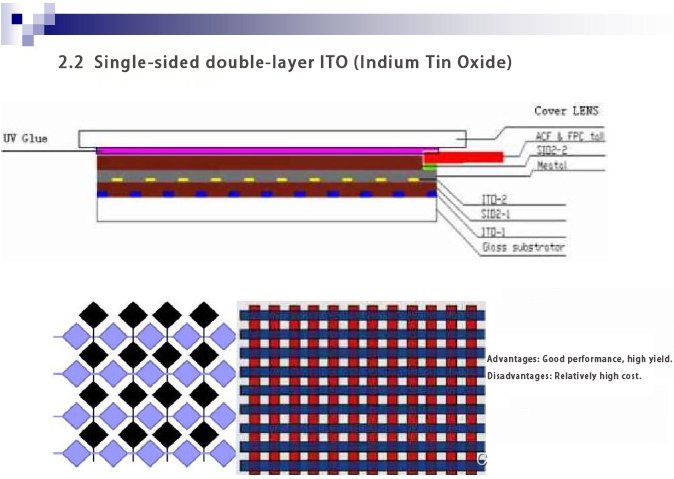

This method uses multiple ITO layers arranged in an X-Y matrix. When touched, capacitance changes at the contact point, which is detected and calculated via X and Y scanning. This architecture supports multi-touch functionality.

Comparison:

• Surface Capacitive: Mature technology, no multi-touch, higher cost, widely available in various sizes.

• Projected Capacitive: Supports multi-touch, more suited for small and medium screens, still developing.

.png)