Have you seen how factories, hospitals, and stores use screens that work perfectly even with wet hands or bright sunlight? Industrial touch screens are heavy-duty versions of your daily screens. Unlike your phone or tablet, these are built tough—they’re waterproof, scratch-resistant, and work in extreme heat or cold.

For example, an IP65 waterproof touch panel won’t quit if it gets splashed, and a sunlight-readable touch display stays clear even outdoors. From helping doctors monitor patients to running cash registers in busy stores, these screens are everywhere.

I’ll show you how they work, why industries rely on them, and what makes them so tough. Keep reading!

Types of Touchscreen Technologies: A Comparative Analysis

Let’s break down how different touchscreens work – because not all screens are the same!

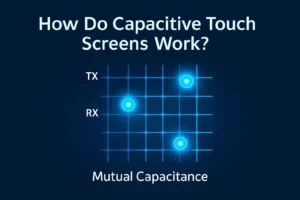

How Capacitive Touch Screens Work

Imagine your smartphone. Capacitive touch screens use your finger’s tiny electric charge (yes, your body has electricity!) to detect touches. They’re super responsive and work great for interactive touch screens like tablets or kiosks. But gloves? Nope – they block the charge. These screens are everywhere because they’re smooth, clear, and handle multi-touch (like zooming in on photos).

PCAP Touch Screens: Precision for Industrial Use

Have you ever seen a factory robot with a screen that works perfectly even with grease or dust? That’s PCAP (Projected Capacitive). PCAP can sense touches through thick gloves or protective glass, unlike regular capacitive screens. Hospitals use them too – think X-ray machines where accuracy is life-or-death. They’re pricier but last longer in tough settings.

Resistive Touch Screens: Cost-Effective Solutions

These are the “old faithful” of touchscreens. Resistive screens have two layers that press together when you tap – like old ATMs or restaurant menus. They work with any stylus, glove, or dirty finger. Downsides? Less clear and no multi-touch. But if you need cheap and reliable (think warehouse inventory systems), they’re perfect.

Quick Comparison

| Feature | Capacitive | PCAP | Resistive |

| Works with gloves? | ❌ | ✅ | ✅ |

| Cost | $$ | $$$ | $ |

| Best for | Phones, tablets | Factories, hospitals | ATMs, rugged devices |

Evolution of Touch Screen Technology

From clunky prototypes to tough industrial tools – here’s how touchscreens got so smart!

Milestones in Touch Screen Development

- 1965: Engineer Eric Johnson made the first capacitive touchscreen for air traffic control – it only worked with fingers, not gloves!

- 1971: Dr. Samuel Hurst invented resistive touchscreens, which later powered ATMs and POS systems.

- 1982: The University of Toronto cracked multi-touch tech, letting screens handle zooming and swiping.

- 1993: IBM’s Simon phone brought resistive screens to mobiles (but you needed a stylus!).

- 2006: LG’s Prada phone used capacitive screens – a month later, the iPhone changed everything.

Advancements in High-Brightness Touch Displays

Ever tried using a phone in sunlight? High-brightness touch displays fix that! Modern screens like Faytech’s 1000 NITS monitors use:

- Optical bonding: Glues the screen layers to cut glare.

- Anti-glare glass: Scatters light so you can see even at noon.

- IP65/IP69K ratings: Survive dust storms or heavy rain – perfect for outdoor touch displays in bus stations or stadiums.

These sunlight-readable touch displays now help menus at outdoor cafes, info kiosks at airports, and even ski resort maps!

Fun Fact: Today’s industrial screens are 3x brighter than your TV – that’s why they work in deserts or icy winters!

Advantages of Industrial Touch Screens

Why do factories and hospitals keep choosing these tough screens? Let’s find out!

IP65 Waterproof Touch Panels for Harsh Environments

Imagine a factory floor where machines spray water or dust flies everywhere. Normal screens would fry, but IP65 waterproof touch panels laugh it off. The “IP65” rating means two things: total dust protection (like a sealed jar) and defense against water jets (think heavy rain or hose-down cleaning). For example, Faytech’s screens work flawlessly even when covered in grease or splashed daily. Hospitals use them too – nurses in gloves can tap X-ray monitors without missing a beat. These screens don’t just survive messes; they stay responsive, making them perfect for outdoor kiosks, food processing plants, or dusty construction sites.

Space Efficiency and Multi-Touch Functionality

Ever seen a cluttered control room with keyboards, mice, and monitors? Industrial touch screens fix that. They’re all-in-one – no extra gadgets needed. This saves space (critical in tight factories) and cuts cable chaos. But here’s the cool part: multi-touch functionality. Like zooming on your phone, workers can pinch-to-resize blueprints or swipe through machine controls with two fingers. Need to adjust a 3D model? Rotate it with a twist gesture. This isn’t just fancy – it’s faster. For instance, fixing a mold design takes minutes instead of hours when you can tweak details directly on the screen.

Industrial Touch Screens in Manufacturing, Healthcare, and Retail

Let me show you how industrial touch screens keep factories humming, hospitals healing, and stores buzzing – all with just a tap!

Medical Touch Screen Monitors for Patient Care

Imagine a nurse checking a patient’s heart rate without fumbling with buttons. Medical touch screen monitors make this easy. These screens are designed to work in sterile rooms, even with gloved hands. For example, during surgeries, doctors use them to control X-ray machines or view MRI scans instantly. They’re also IP65 waterproof, so spills during emergencies won’t fry the system. In ICUs, these monitors display real-time stats like blood pressure, letting staff act fast if something’s wrong. No more flipping through charts – everything’s right on the screen!

POS Terminal Touch Screens in Retail

Ever ordered a burger at a fast-food kiosk? That’s a POS terminal touch screen! These screens speed up checkouts by letting cashiers tap orders instead of typing. In busy stores, they cut waiting time by half. For instance, a clothing store uses them to scan barcodes, apply discounts, and print receipts – all on one device. Some even let customers customize orders, like adding extra cheese to a pizza. Plus, they track inventory automatically. When jeans sell out, the screen alerts staff to restock. No more “Sorry, we’re out of your size!”

Embedded Touch Screens in Automation Systems

Picture a car factory where robots weld parts perfectly. Embedded touch screens are the brains here. They’re built into machines to control assembly lines. Workers tap the screen to adjust settings or spot errors. For example, if a robot misaligns a door, the screen flashes red, and the line pauses. These screens also connect to sensors and cameras, giving live updates on production. In packaging plants, they manage conveyor belts – speed them up, slow them down, or stop them if a box jams. It’s like having a remote control for the whole factory!

Optimizing Sunlight Readable Touch Displays for Outdoor Use

Ever tried using your phone at the beach? Now imagine doing that all day at work! Sunlight readable touch displays solve this problem for outdoor kiosks, marine equipment, and construction sites. These screens use special tech to boost brightness – up to 1,500 nits (that’s 3 times brighter than your TV!). They also have anti-glare coatings that scatter sunlight, so you can see even at high noon. But it’s not just about brightness. IP65 waterproof panels keep these displays working in rain, snow, or salty sea spray. For example, touchscreens on fishing boats stay responsive even when splashed with seawater. This combo of high visibility and toughness means outdoor workers can tap, swipe, and pinch-zoom without squinting or worrying about damage.

Outdoor & Waterproof Touch Display Solutions

For industries needing screens that survive extreme conditions, EverGlory Ltd.’s Marine & Aviation Solutions offer IP67-rated waterproof touch panels tested in saltwater environments. Their High-Brightness Outdoor Displays achieve 1,500 nits brightness, ideal for construction sites or stadium kiosks.

Custom Touch Screen Solutions

Need a screen for niche applications? Explore EverGlory’s Custom Design Services, which handle everything from medical-grade sterilization to freezer-compatible interfaces. Their Industrial Displays page showcases ruggedized screens for factory robots and HMI systems.

Curious about touchless tech? Check their Innovations Blog discussing haptic feedback and predictive touch applications in aviation and healthcare.

Why Choose EverGlory?

- Proven Expertise: 14+ years in Industrial and Medical sectors.

- Global Reach: Serving 30+ countries with Competitive Pricing.

- Case Studies: See real-world success stories in their Customer Reviews section.

Conclusion

Industrial touch screens have become the backbone of modern manufacturing, healthcare, and retail. From waterproof displays on ships to custom solutions in specialized factories, these rugged interfaces keep businesses running smoothly. As we’ve seen, the technology continues to evolve, with touchless controls and haptic feedback on the horizon. Companies like EverGlory Ltd. are at the forefront, developing durable, tailored touch solutions that meet the unique challenges of every industry. Whether it’s a sunlight-readable kiosk or a complex control panel, these screens prove that with the right tech, even the toughest jobs can be just a tap away.

.png)