An industrial touch screen lets you control machines and systems with just a tap or swipe. You often find these screens in places where dust, water, and extreme temperatures challenge normal devices. Many use tough glass and have an IP65 rating, so they keep working even in harsh conditions. You can count on these screens to last a long time, work with older systems, and give you an easy way to manage complex tasks.

Key Takeaways

- Industrial touch screens are made to handle tough places. They can block dust, water, and very hot or cold weather. This makes them good for factories and outside jobs.

- Pick the right touch screen for your needs. Capacitive screens are very sensitive and clear. Resistive screens work when you wear gloves. Infrared screens are strong and can be used in many ways.

- Always look at the IP rating before you buy. A higher IP rating gives more safety from dust and water. This helps your screen last longer.

- Think about the screen’s size and how bright it is. Good brightness helps you see better and keeps you safe. This is important in both bright and dark places.

- Buying industrial touch screens can save you money over time. They last longer than regular screens. You will not need to replace them as often.

What Is an Industrial Touch Screen

Definition

An industrial touch screen is a special display. You can control machines by touching it. These screens are used in factories, hospitals, and stations. They help people use equipment fast and safely. Regular screens cannot handle tough places. Industrial touch screens work even with dust, water, or heat.

Key Features

Industrial touch screens are different from regular ones. Here is a table that shows how they compare:

| Feature | Industrial Touch Screens | Consumer-Grade Touch Screens |

|---|---|---|

| Rugged Build Quality | Reinforced casings, IP ratings for protection | Standard build quality |

| Operating Temperature Range | -30°C to 80°C | Limited temperature range |

| Brightness & Contrast | Up to 1500 nits, high contrast ratios | Lower brightness, standard contrast |

| Connectivity | Industrial I/O ports, secure connections | Basic connectivity options |

| Product Lifecycles | 5+ years availability, repair services | Shorter lifecycles |

Industrial touch screens have many helpful features. They are strong and can take bumps or drops. You can use them in hot or cold places. They do not break if they get wet or dusty. You can use gloves or a stylus to touch the screen. The screen is bright and easy to see. You can put them on many types of machines. They last a long time and work for years.

Tip: Always look at the specs before you buy an industrial touch screen. This helps you choose the best one for your needs.

Why Choose Industrial-Grade

Durability

You need a screen that can do hard work. Industrial touch screens use strong materials. These materials help the screens last a long time. They stop scratches and impacts. Some even protect against explosions. Here are some materials used in these screens:

- High-strength glass fiber

- Alumina

- Sapphire

- Tempered glass

- Silicone

- High-strength engineering plastics

- Explosion-proof film

- Polymer composites

These materials keep your screen safe from harm. You can use your device every day. It will not crack or break in rough places.

Environmental Resistance

Industrial places can be tough. Dust, water, and chemicals are everywhere. You need a screen that works all the time. Industry standards show which screens protect best. Look at this table to see some important standards:

| Standard | Description |

|---|---|

| IP (Ingress Protection) | Gives protection from dust, water, and other things. |

| NEMA 12/4/4X | Shows protection from dust and water in tough places. |

Many industrial touch screens meet these rules. For example, resistive sensors follow NEMA 12/4/4X and IP65/66. This means your screen stays sealed and safe.

Note: Always check the rating before you pick a screen.

Performance

You want your screen to work well anywhere. Industrial touch screens work in places with shaking or big temperature changes. Here is how they do it:

| Feature | Description |

|---|---|

| Vibration Resistance | These screens can handle strong shaking. They are good for factories. |

| Wide-Temperature Operation | They work in very hot or cold places. They stay reliable in many conditions. |

| IP65/IP68-Rated Sealing | They keep out dust and water. This makes them last longer. |

With these features, your screen will not stop working. Machines can shake or weather can change. Your industrial touch screen will keep working. This helps your work stay safe and smooth.

Industrial Touch Screen Types

There are three main types of industrial touch screens. These are capacitive, resistive, and infrared. Each type works in a different way. Each one is good for certain jobs. Let’s see how they work and where you might use them.

Capacitive

Capacitive touch screens sense your finger’s electricity. You see this in smartphones and in factories. Projected capacitive (PCAP) is great for tough places.

Here is a table that shows the main good and bad points of capacitive touch screens:

| Advantages | Disadvantages |

|---|---|

| High sensitivity and responsiveness | Generally more expensive |

| Better visual clarity | Inoperable with most gloves or non-conductive stylus |

| Multi-touch capabilities | Vulnerability to electromagnetic interference (EMI) |

Capacitive screens react fast and show clear pictures. You can use more than one finger at a time. This helps you zoom or turn images. PCAP works even with thick gloves or covers. It does not scratch easily. It keeps out water and dirt. You can use it outside or in dirty places. PCAP screens have high IP ratings. This means they block dust and water.

Tip: For tough jobs, PCAP capacitive touch screens are strong and last long.

Here is a price chart to help you compare costs:

| Touch Screen Type | Price Range | Characteristics |

|---|---|---|

| Capacitive Touch Screens | $20 – $1,000+ | Higher cost due to advanced technology, multi-touch capabilities, and durability. |

| Resistive Touch Screens | Generally lower than capacitive | More cost-effective, suitable for rugged conditions, glove operation, and liquid resistance. |

Resistive

Resistive touch screens work when you press two layers together. You can use your finger, a pen, or gloves. This makes them good for many jobs.

Here are some main reasons to pick resistive touch screens:

- They are very accurate, even with gloves or pens.

- They block dust, dirt, water, and chemicals.

- They work well in many places.

- You can touch them with almost anything.

- They save money for businesses.

Here is a table that shows how resistive touch screens do in hard places:

| Feature | Description |

|---|---|

| Dust Resistance | Highly resistant to dust and dirt. |

| Liquid Resistance | Capable of functioning in the presence of liquids. |

| Contaminant Resistance | Effective against various contaminants. |

Resistive screens are smart for dirty or wet places. They keep working when things get messy. Many factories use them because they are cheap and work well.

Infrared

Infrared touch screens use invisible light beams. When you touch the screen, you break the beams. The system finds the spot you touched.

Here is a table that shows what makes infrared touch screens special:

| Feature | Description |

|---|---|

| Durability and Reliability | Protected components and environmental resistance make them suitable for harsh conditions. |

| High Clarity and Brightness | Unobstructed display ensures original clarity and brightness, ideal for high-definition use. |

| Multi-Touch Capability | Supports multiple touch points for complex gestures and multi-user interactions. |

| Versatile Input Methods | Detects any object, including fingers and gloves, providing flexibility in various environments. |

| Fast and Accurate Response | Quick touch detection and high precision enhance user experience. |

| Low Maintenance | Minimal wear and tear leads to lower maintenance needs and a longer lifespan. |

Infrared screens do not need you to touch the glass. You can use gloves, a pen, or anything else. The screen stays clear because nothing covers it. These screens are good for bright places. They last a long time because they do not wear out fast.

Note: Each type of industrial touch screen is best for certain jobs. Think about where you will use it before you choose.

Choosing an Industrial Touch Screen

Picking the best industrial touch screen needs some thought. You should think about where you will use it. You also need to know what you will use it for. The size and how bright the screen is are important. You must check the IP rating and what ports it has. All these things help you get a screen that works well and lasts long.

Environment

Think about the place where you will put your screen. Factories and work sites can be rough. Dust, water, heat, and shaking can hurt normal screens. You want a screen that can handle these problems.

Here is a table that shows important things about the environment:

| Environmental Factor | Description |

|---|---|

| Temperature Resistance | Touchscreens must work in very hot or cold places. They should not stop working in these temperatures. |

| Dust Protection | Screens should be sealed so dust cannot get inside. This keeps the parts safe. |

| Water Resistance | Screens with an IP65 rating can keep working if they get wet. |

| Impact Resistance | Screens should not break if you tap them or if machines shake. |

| Electromagnetic Interference | Screens need special covers to block EMI. This helps them work better. |

Tip: Look for screens that are waterproof, block EMI, and can take hits before you buy.

Application

What you do with your screen helps you pick the right kind. Some jobs need fast touch and more than one finger. Other jobs need screens that work with gloves or pens. Here are some ways your job changes what you need:

- Capacitive touch screens react fast and need only a light touch. This helps you finish work quickly.

- Multi-touch lets you use two or more fingers. You can zoom or move things on the screen.

- Tough screens last longer and save you money. You do not have to replace them often.

- Clear screens help you see small details. This is good for careful work.

- Screens that use less power help your machines run longer.

Touch screens can take the place of old buttons and switches. You can use them to watch machines, collect data, and control systems in many jobs.

Note: Think about what you need your screen to do every day. This will help you choose the best type.

Size and Brightness

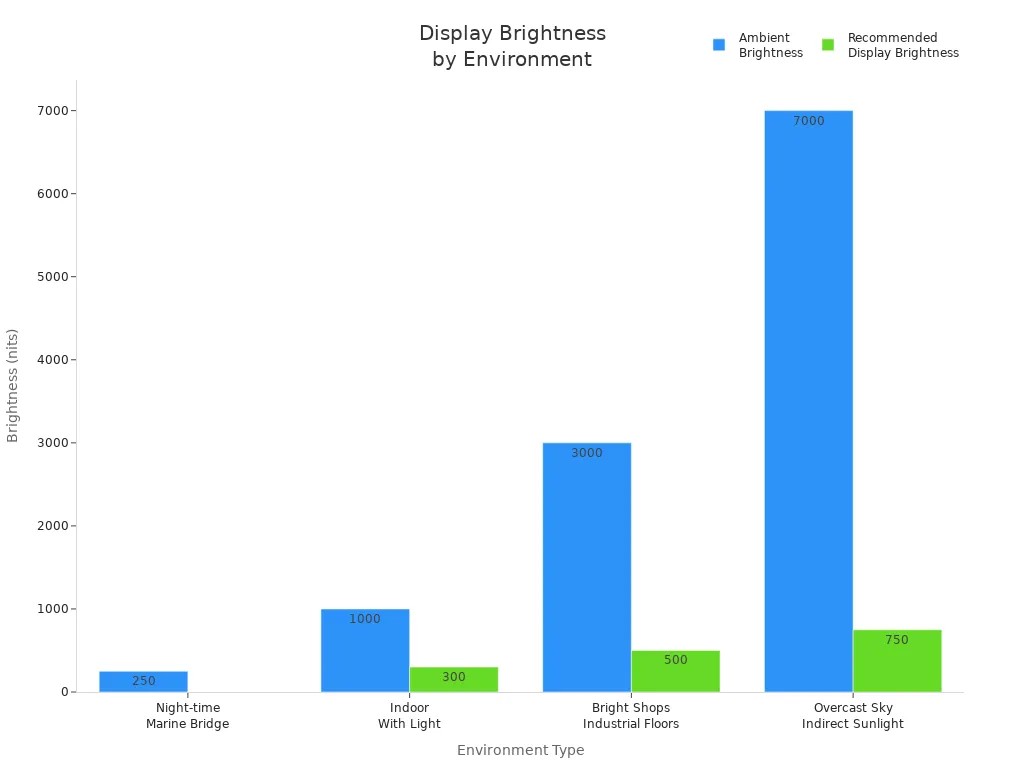

Pick a screen that fits your space and is easy to see. The right size and brightness make your job safer and easier. Different places need different brightness. Here is a table to help you pick:

| Environment Type | Ambient Brightness (nits) | Recommended Display Brightness (nits) |

|---|---|---|

| Night-time Marine Bridge | < 250 | 1 |

| Indoor With Light | ~1,000 | Up to 300 |

| Bright Shops and Industrial Floors | 1,000 – 3,000 | Up to 500 |

| Overcast Sky or Indirect Sunlight | 3,000 – 7,000 | ~750 |

Tip: If you work outside or in bright places, pick a screen with anti-glare.

IP Rating and Interfaces

IP ratings show how well your screen keeps out dust and water. A higher number means better protection. Here is how IP ratings help you:

- High IP ratings like IP6X keep dust out. This protects the inside parts.

- Ratings like IPX5 or IPX7 stop water from getting in. Your screen stays safe if you spill or clean it.

- Strong IP ratings help your screen last longer in hard places.

You also need the right ports to connect your screen. Many screens have HDMI, VGA, DisplayPort, USB, and serial ports. These let you connect to new and old machines. Open frame monitors give you more ways to set up your system.

Note: Always check if your screen has the right ports and ways to mount it for your setup.

Applications

Manufacturing

Industrial touch screens are common in today’s factories. They help you run machines and watch over production lines. You can use them for:

- Human-Machine Interfaces (HMIs) let you work with equipment right away.

- Monitoring systems check data and warn you about problems.

- Control panels help manage how things are made and keep work steady.

Easy-to-use screens help you finish work faster and make fewer mistakes. Watching things in real time helps you see problems before they get worse. These screens are made to be safe and comfortable for workers.

| Feature | Benefit |

|---|---|

| Real-time monitoring | Find and fix slow spots fast |

| User-friendly interface | Do jobs right and quickly |

| Ergonomic design | Stay safe and feel less tired |

Tip: Touch screens in factories can help stop delays and make products better.

Medical

Hospitals and clinics use touch screens for many jobs. These screens make medical tools easier to use and help you care for patients. You can:

- Get patient information fast on monitors.

- Use drug machines with easy controls.

- Run surgery and test tools with quick feedback.

Medical touch screens often have special materials to stop germs. You can use them with clean covers to keep things safe. The simple design helps you learn new tools quickly and make fewer mistakes.

Automation

Automation needs touch screens to work well. You use them to control robots, smart factories, and automatic lines. These screens:

- Make it easy to use pictures and commands.

- Work with old and new control systems.

- Have smart features for Industry 4.0, like fixing problems before they happen.

Touch screens help save money and keep workers safe. You can control hard systems with just a few taps.

Transportation

You see touch screens in cars, trains, and stations. They help you with:

| Application Type | Description |

|---|---|

| Vehicle Diagnostics | Check and fix car systems to work better |

| Passenger Information Systems | Show times, news, and tickets to riders |

| Accessibility Features | Make controls simple for everyone, even people with disabilities |

These screens can take hits, shaking, and bumps. Their strong build means they last longer and need less fixing. You get good results, even in hard places like trains and buses.

Picking the right industrial touch screen helps you save money. It also keeps your work going without problems. Industrial displays can last more than 50,000 hours. They are very strong and do not break easily. Consumer screens do not last as long in hard places.

| Type of Display | Lifespan | Durability Features |

|---|---|---|

| Industrial Displays | 50,000+ hours | Works all day, handles shaking and bumps |

| Consumer Displays | 3–5 years | Breaks more easily in tough places |

You need to look at the screen size, how bright it is, and the IP rating. Make sure the screen fits your job and where you use it. If you are not sure, ask a supplier or expert for help.

FAQ

How do you know if your device has a capacitive touch screen?

Check your device’s manual for details. Try tapping the screen with a gloved finger. If nothing happens, it is probably capacitive. These screens feel smooth. They react fast when you use your bare finger.

What should you do if your capacitive touch screen stops working?

Wipe the screen gently with a soft cloth. Turn your device off and on again. If it still does not work, look for software updates. If you still have trouble, ask your supplier for help.

What is a capacitive touch screen?

A capacitive touch screen senses your finger’s electricity. You do not need to press hard to use it. These screens work quickly and show sharp images. Many phones and industrial machines use this kind of screen.

How does capacitive touch screen technology make your work easier?

- You can tap or swipe to use the screen.

- The screen reacts fast to your touch.

- You see clear pictures, even in bright light.

- Multi-touch lets you zoom in or turn things.

Tip: Capacitive screens help you work faster and make fewer mistakes.

.png)