.png)

.png)

| Product model | EG-SY-10.1-A-1609V1 |

|---|---|

| Type | Projective Capacitive |

| Connector | COB |

| Screen Diagonal | 10.1 [16:9] |

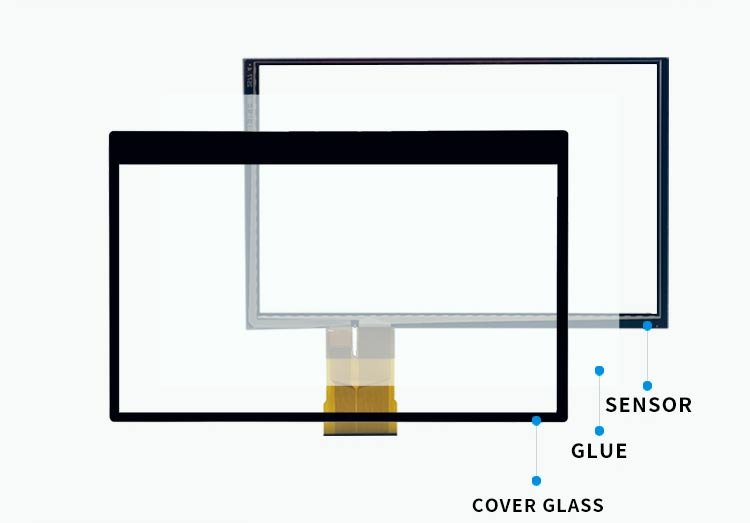

| Structures | G+G |

| Outline Dimension | 153.20(W)*251.00(L)±0.2mm |

| View Area | 126.20(W)*224.00(L)±0.2mm |

| Active Area | 127.20(W)*225.00(L)±0.2mm |

| Sensor Thickness | 0.55±0.05mm |

| Cover Thickness | 2.0±0.2mm |

| Total Thickness | 2.75±0.2mm |

| Tail Length | 65.07mm |

| Transmittance | >85% |

| Input Mode | Finger |

| Support Points | 1~10 |

| Interface | USB |

| Supply Voltage | USB 5 V |

| Power Consumption | <0.6 W |

| Report Rate | >100 Hz |

| Response Time | <50 ms |

| Linearity | X≦1.0%, Y≦1.0% |

| Life Time | >50,000,000 times |

| Product model | EG-SY-10.1-A-1609V1 |

|---|---|

| Type | Projective Capacitive |

| Connector | COB |

| Screen Diagonal | 10.1 [16:9] |

| Structures | G+G |

| Outline Dimension | 153.20(W)*251.00(L)±0.2mm |

| View Area | 126.20(W)*224.00(L)±0.2mm |

| Active Area | 127.20(W)*225.00(L)±0.2mm |

| Sensor Thickness | 0.55±0.05mm |

| Cover Thickness | 2.0±0.2mm |

| Total Thickness | 2.75±0.2mm |

| Tail Length | 65.07mm |

| Transmittance | >85% |

| Input Mode | Finger |

| Support Points | 1~10 |

| Interface | USB |

| Supply Voltage | USB 5 V |

| Power Consumption | <0.6 W |

| Report Rate | >100 Hz |

| Response Time | <50 ms |

| Linearity | X≦1.0%, Y≦1.0% |

| Life Time | >50,000,000 times |

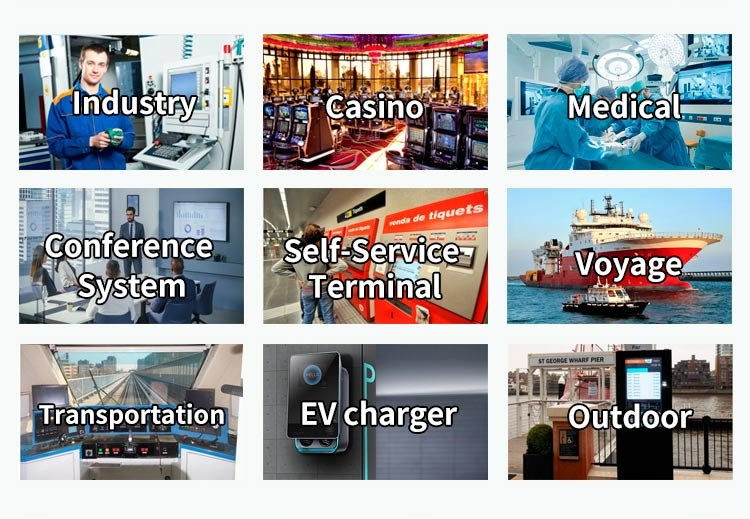

This 10.1-inch HMI touch panel is designed for industrial control environments where water spray, dust, and frequent cleaning are common.

Therefore, it focuses on a sealed front, stable PCAP touch, and practical integration for cabinets and wall-mounted terminals.

In addition, glove and wet touch tuning can be configured based on your actual operator workflow.

If the unit is used outdoors or near strong sunlight, consider brightness + glare control + bonding together.

See sunlight readable touch displays.

For outdoor kiosks and similar systems, review

outdoor touch screen solutions.

| Item | Specification |

|---|---|

| Screen size | 10.1 inch |

| Touch technology | Projected capacitive (PCAP), multi-touch (configurable) |

| Waterproof rating | Front panel IP65 (typical); sealing stack-up depends on enclosure integration |

| Cover glass | Tempered / chemically strengthened glass (options: AG/AR/AF coatings) |

| Brightness | Standard / high brightness option (define target nits for your environment) |

| Operating temperature | Industrial range option (define target range) |

| Interface | Display interface + USB touch (confirm based on final configuration) |

| Mounting | Wall-mounted / bracket mounting (confirm holes, VESA, or custom) |

For PCAP fundamentals and tuning context, see

how capacitive touch screens work.

Start with the practical notes in

waterproof touch screens (IP65).

For a validation workflow before deployment, use the

touchscreen test checklist

and the more detailed

touchscreen tester guide.

The front is designed for IP65 in typical configurations. However, final waterproof performance depends on enclosure sealing, connectors, and cable entry design.

Yes, PCAP can be tuned for glove and wet touch. Therefore, define glove type and validate under real water film conditions before approval.

Wall brackets or custom mounting patterns are common. Share your mounting drawing so the bezel pressure and sealing can be designed correctly.

Most cases come from EMI noise, grounding issues, or cable routing near power lines. Re-testing after assembly is essential.

Please share screen size, target IP level, brightness target, glove/wet touch needs, EMI sources, and your enclosure drawing.

DongGuan Ever Glory Photoelectric Co., Ltd is a national high-tech enterprise, founded in 2021, Our Parent company ShenZhen Ever Glory was found in 2011, with 20,000 m2 production facilities located in Dongguan city. We are dedicated to producing top quality G+G,G+F,G+FF Projected Capacitive Touch Panel , Touch Display module and Touch Monitor & Panel PC in house .

We have:

* 3 years warranty – Why offering 3 years warranty while the most of competitor only offer1 year ? it’s backup by our Stable product design, Strict Quality Control , and strong technical Support capability .

* More than 12 years experience – Even though 12 years is not long history , But as the forerunner and preacher in China Market, all our history and experience is about PCAP .

* 5 times QC inspection – from raw material to finished product ,100% inspection on each piece 1. 100% Incoming material inspeciton

2. 100% Function test after Sensor+FPC lamination ,

3. 100% Physical inspection while bonding cover glass + Sensor

4. 100% Function and physical inspection after lamination process ( Before UV curing )

5. 100% Function test while loading the firmware controller

* Low MOQ – We are offering 50-200pcs MOQ for customized touch panels which competitors.Requires 500-1000pcs/model , And we have strong capability to deal with complex design .

* Flexible Customization – For professional applications, it usually requires long testing period and repeated pilot runs to test the reliability of products on site, we are able to coordinate with customers flexibly with small quantity .

* 7-15 working days delivery time – For standard models, We can ship within 3 working days upon order confirmation, For bulk order, we usually can ship within 15 working days .

* Technical Support – Our sales team are very energetic and always ready to assist you for any demand , Our engineers are able to handle 98% of firmware tuning and troubleshooting by ourself.

![]()

![]()

![]()

![]()

![]()

Standard packing with carton or wooden box

1.Our touch panel is safely sealed & packed with anti-static bag and foam wrapping.

2.Flexible packing options with carton or wooden box.

3. Shipping methods :DHL,UPS,FedEx,TNT,Air freight,LCL/FCL Sea freight.